How to buy

Privacy | Do not sell or share my personal information | Cookie preferences | Report noncompliance | Terms of use | © 2023 Autodesk Inc. All rights reserved

Fusion 360 with Netfabb® software is available as Premium, Ultimate, and Netfabb Local Simulation. Optimize additive manufacturing processes and simulate metal additive build workflows.

Arrange many parts in the build space with as little space as possible, while avoiding collisions and interlocking

Define build strategies and toolpath parameters for maximum surface quality, part density, and speed

ULTIMATE ONLY

Fill solid volumes with standard or custom lattices to create unique material properties

ULTIMATE ONLY

Test how your optimized designs will perform using built-in Autodesk Inventor Nastran simulation

NETFABB LOCAL SIMULATION ONLY

With metal powder bed fusion (MPBF) and direct energy deposition (DED), use multiscale modeling to simulate the thermal and mechanical response of parts and help reduce build failures

ULTIMATE ONLY

Automatically verify and optimize lattice and skin elements to meet load requirements and reduce weight

Import, analyze, and repair models

Import models from a variety of CAD formats and use repair tools to quickly correct errors. (video: 3 min.)

Modify models for production

Make your models production ready by adjusting wall thicknesses, smoothing rough areas, and more. (video: 2:26 min.)

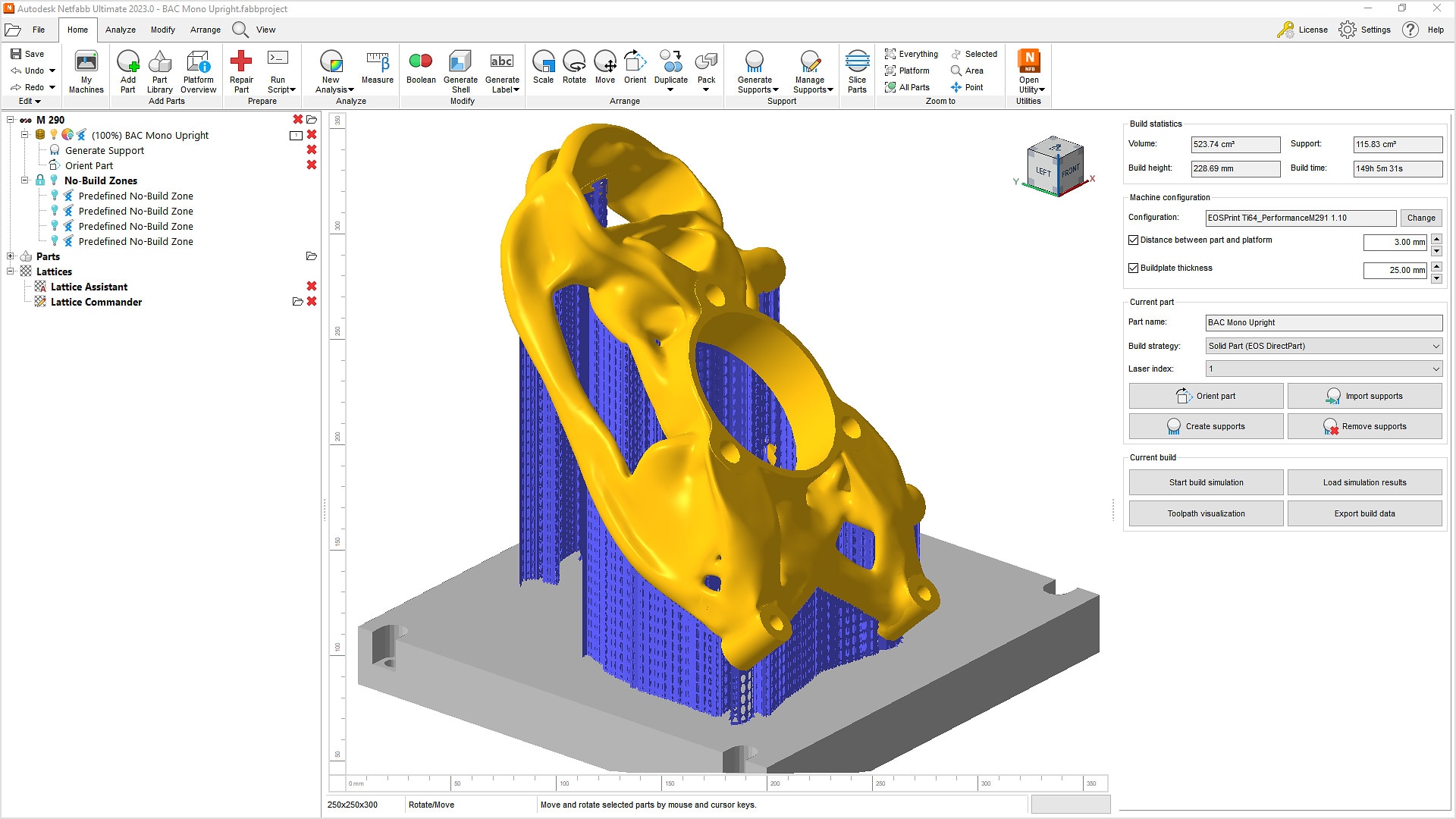

Configurable build supports

Identify areas that require support and use semi-automated tools to generate support structures. (video: 1:47 min.)

Automatic packing

Use 2D and 3D packing algorithms to optimally place parts within the build volume.

Report generation

Create custom reports that include critical information for manufacturing and quoting.

Additive toolpaths

ULTIMATE ONLY

Develop build strategies and define toolpath parameters for maximum surface quality, part density, and speed.

Automation

ULTIMATE ONLY

Automate common preparation tasks including import, analysis, repair, packing, slicing, and tool pathing.

Internal lattice structures

Create lightweight parts with performance characteristics specific to your application.

Topology optimization

ULTIMATE ONLY

Generate forms that are optimized for stiffness and weight, based on the loads and constraints of the part.

Integrated performance analysis

ULTIMATE ONLY

Test how your optimized designs will perform using built-in Inventor Nastran simulation.

Lattice optimization

ULTIMATE ONLY

Automatically verify and optimize lattice and skin elements to meet load requirements and reduce weight.

Selective space structure (3S)

ULTIMATE ONLY

Fill solid volumes with standard or custom structures to create unique material properties for your part.

Machine workspaces

Select from the most popular additive manufacturing machines to configure the Netfabb workspace to your process.

Solutions for machine manufacturers

Netfabb works with a range of OEMs to create integrated printing experiences configured for specific machines.

Predict the thermomechanical response of additive parts during the MPBF and DED manufacturing processes.

MPBF

Use multiscale modeling to predict the thermal and mechanical response of parts and help reduce build failures.

DED

Simulate full builds for both powder-fed and wire-fed DED processes with Netfabb Local Simulation.

Fast, predictive simulation

Adaptive meshing and the physics-based, multiscale approach help keep processing time low and accuracy high. (video: 1:06 min.)

Small-scale simulation

Generate PRM files based on chosen material and process parameters for increased accuracy.

Part-scale simulation

Simulate the additive manufacturing process for powder bed fusion to identify potential causes of build failures.

Simulate the entire build plate

Capture interactions between parts and the distortion of the build plate.

Simulate stress relief

Design appropriate heat treatment cycles by inputting the temperature versus time curve of the desired process.

Detect recoater interference

Identify possible build failures with powder bed processes that may cause equipment damage.

Avoid support failure

Predict support failure to aid in the design and placement of support structures.

Predict part distortion

Predict how metal additive manufacturing parts will deform to help reduce build failures.

Account for part/powder interaction

Model the conduction of energy into the loose powder to increase your model’s accuracy.

Calculate residual stresses

Accurately calculate residual stresses and strains built up during the additive manufacturing process to identify likely regions of failure.

Simulate response after wire-cutting

Simulate the mechanical response of a deposited part after removal from the build plate to calculate the final distortion.

Predict hot spots and lack of fusion

Apply multiscale modeling to predict regions of a build that get too hot or not hot enough during processing.

Compensate for distortion

Automatically compensate geometries based on simulation results to achieve the desired shape when printed.

STUDY

Experimental data shows improved accuracy with the explicit modeling of loose powder and the interaction between parts.

STUDY

Netfabb simulates the delamination of the part from the region where the support structure on a component experienced failure.

STUDY

Netfabb Simulation accurately calculates temperature and distortion during the powder bed fusion process to within 5% error of the measurement.